Our approach, origin and the pillars of our sustainability

For Walter K., sustainability is a question of commitment

Through our behavior, we want to help preserve our natural resources and protect our environment from harmful influences.

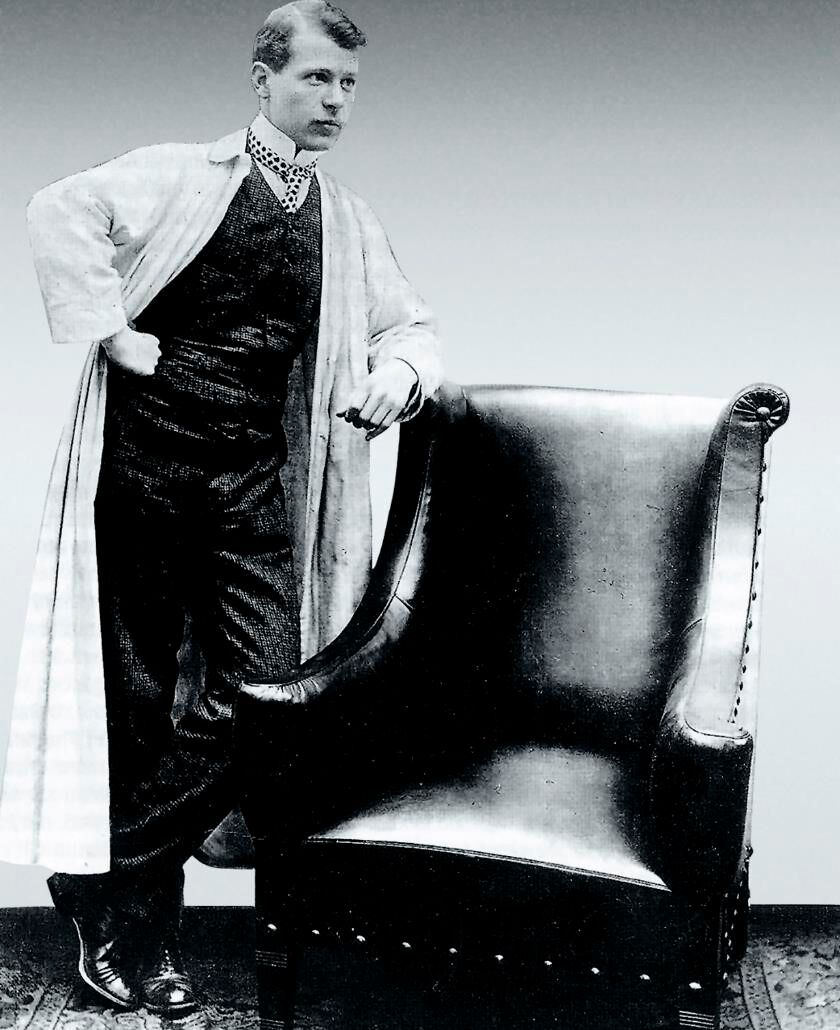

Enduring quality and responsible business practices have driven us for 160 years

Minimal use of materials, excellent craftsmanship – and a focus on the human being

To this day, we adhere to the principles of Bauhaus: Reduction and simplicity are key concepts of the Bauhaus philosophy. Less is often more. By reducing things to the essentials, we can create durable products that last. Because minimal design is sustainable design.

The Bauhaus values were right a hundred years ago and still characterize who we are today

1. The purpose of furniture is people.

2. Beauty knows no time.

3. Craftsmanship is the refinement of design.

4. A product is good when it becomes valid.

5. The more we leave out, the more sustainable we are.

We produce in Germany

Regional Cluster with selective partners

Our sourcing has always been regional

Since 1985, we have been a member of the Deutsche Gütegemeinschaft Möbel (German Furniture Quality Association)

We have joined forces with other furniture manufacturers and suppliers who are committed to high quality standards and sustainable production in the Quality Association. The DGM develops the requirements for the internationally valid RAL-GZ 430 quality and test specifications.

- The DGM has over 130 members in Germany and abroad.

- Common standards for furniture production: sustainable, high quality, safe.

- Requirements partly exceed the already high legal requirements.

- The focus is on qualitative, ecological, social and procedural aspects.

- Vision: durable, functional, safe, health-friendly and environmentally friendly furniture.

Certified environmental management according to DIN EN ISO 14001

How does that translate into our day-to-day work?

What environmental targets have we set for 2025?

- Switch to 100% green electricity

Since 2025, we have been using exclusively green electricity for our Herrenberg and Mötzingen sites. - Commissioning of further photovoltaic systems

Through a shareholder investment in the photovoltaic systems at our Herrenberg site, we can strengthen our supply of self-generated electricity. The electricity generated is used directly by us. - Recycling of production waste

We have launched a research project to promote the circular economy and sustainably reduce waste. We recycle the production waste from our leather by using it to produce high-quality recycled leather. In order to evaluate the practicality and quality, the recycled leather is first tested in small parts of our furniture. If the application is positive, we aim to gradually expand it to other product areas.

What have we established and accomplished?

- Returnable packaging with suppliers, where possible

- Recyclable packaging for specialist retailers

- all print media

- all packaging

- Protective covers made from recycled material

- 50% reduced energy consumption through efficient vacuum pump

- 5% material savings through cutting optimization

Our headquarter building as well as our production facility are aligned with green building and operational practices

Our headquarters in Herrenberg (Germany) - built according to a comprehensive ecological concept. Awarded in 2008 by the Baden-Württemberg Chamber of Architects for Exemplary Building and by the Association of German Architects with the “Award for Good Buildings”.

Only 10 kilometres from Herrenberg: our production site in Mötzingen - awarded by the Baden-Württemberg Chamber of Architects for “Exemplary Building”. We are currently renovating various parts of the site - this will enable us to save even more energy.

Our headquarters in Herrenberg (Germany)

Our production site in Mötzingen